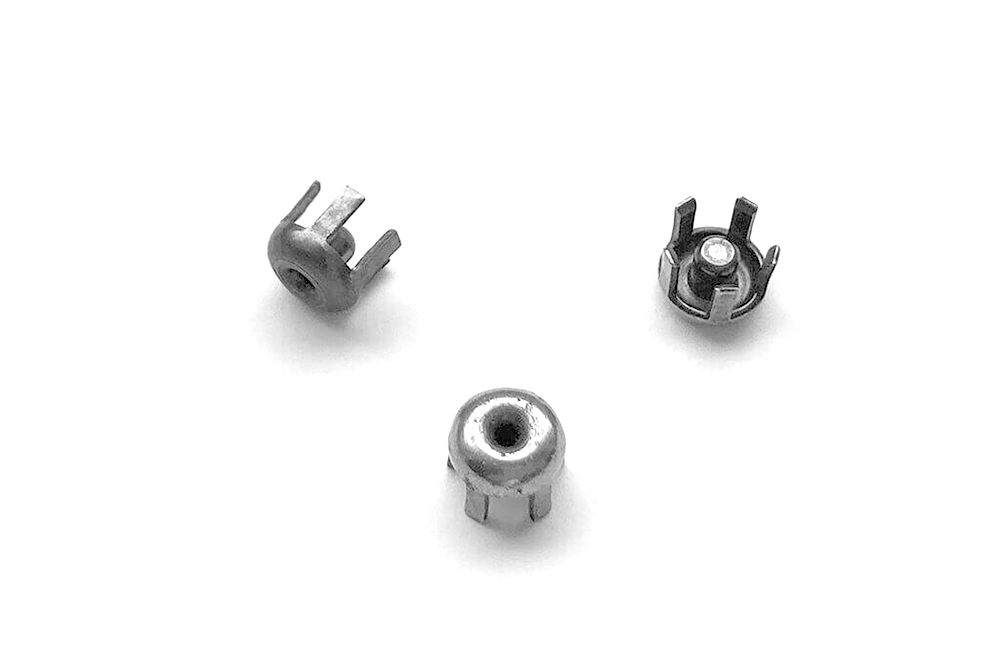

Deep-drawn parts

The real draw.

Deep drawing is a manufacturing process that transforms flat sheet metal into three-dimensional components through plastic deformation. This process has numerous advantages which increase production efficiency and quality.

One of the primary advantages lies in the optimum material usage and reduced material consumption. The targeted sheet-metal forming process minimises material waste and reducing costs.

Deep drawing enables the production of components with complex geometries using a faster and more streamlined process. This results in more efficient production and also significantly reduces production times.

In addition, deep drawing is also capable of reducing the component weight while retaining the required strength and durability. The ability to produce lighter components without sacrificing strength is is a vital advantage for automotive and aerospace industries, for example, where weight savings directly impact performance and efficiency.

Deep drawing processes are also highly versatile. The ability to utilise a variety of materials metals such as steel, aluminium and copper to plastics enables the production of parts with highly specific product and material characteristics and benefits a wide range of industries.